KANBAN: Made in Japan

KANBAN: Made in Japan

Deep Purple ” Made in Japan

(source: http://cronicasyversiones.com)

KANBAN is a task management technique originating from Toyota’s Just In Time (JIT).

Due to its simplicity and efficiency, it has spread to all kinds of processes, including software development and agile business management.

This is one of those posts that was left in draft due to laziness, lack of time, or changing interests, but upon reading it 3 years later, I have decided to rescue it.

KANBAN originates from “Made in Japan” like the legendary 1972 Deep Purple album. Dream Theater released an interesting revision in 2007.

KANBAN and PROCESSES

Simplifying a lot, a process is a pipeline that receives inputs (water), processes them (transports), and generates outputs (water).

A pipeline represents the simplest process

The amount of water at the output depends on what enters but also on the characteristics of the pipeline (diameter and length) and its inefficiencies (leaks).

One of the differences of KANBAN compared to other ways of managing work is that KANBAN does not determine how to do things. KANBAN determines what to do and visually reflects what is being done without ever telling you how.

In KANBAN, it is your definition of processes that determines how you do things. You will be more productive based on how efficient your processes are.

APPLIED TO SOFTWARE

In the software development cycle, similar to the pipeline, we have an input (requirements, user stories, …), a process or transport (analysis, design, development, testing, …), and an output (deliverables, software functioning in production, …).

The diameter and length of the pipeline would correspond to the team’s capabilities and our development processes. The leaks, the inefficiencies in those processes. Greater capacity and better processes will imply greater execution capacity.

Finally, quality (internal and external) would depend on aspects such as the cleanliness of the pipeline, its material, etc.

HOW DOES IT WORK?

https://www.flickr.com/photos/otacke

KANBAN has simple rules:

- Visualize the work and workflow

- Limit work in progress (WIP)

- Make rules explicit

- Measure and improve: Lead Time (customer perception) and Cycle Time (actual execution time).

In the first 3 minutes of the following video, Axosoft introduces how KANBAN works and its possible combination with SCRUM.

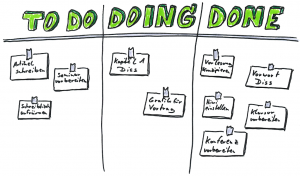

VISUALIZING THE WORK

KANBAN uses KANBAN boards like the one in the image above. These boards can have as many columns as there are states in the workflow. The use of this board allows visualizing the flow of work between states and, therefore:

- Detect bottlenecks early on.

- Know and CONTROL WORK IN PROGRESS.

- SEE THE finished work (which can be an important motivational element).

LIMITING WORK IN PROGRESS

The goal should always be to Finish (“STOP STARTING & START FINISHING”) so that a task is not started until another is finished. This way, it allows:

- Detecting bottlenecks.

- Avoiding the ABUSE OF MULTITASKING, which causes lower efficiency, errors, and stress.

MAKING RULES EXPLICIT

It is essential that the rules are visible to the entire team. These rules determine the workflow and can regulate, for example:

- The maximum WIP (number of tasks) in each STATE.

- How urgent tasks are managed (that cannot follow the normal flow).

- How tasks with FIXED DATE are managed.

- What the COLORS of the cards mean.

MEASURE AND IMPROVE, IMPROVE, IMPROVE, …

The most important metrics in KANBAN are Lead Time (time perceived by the customer) and Cycle Time (actual execution time). This way, KANBAN seeks continuous improvement in the process in terms of:

- QUALITY

- DEADLINES

- COSTS

DEEP PURPLE

In 1972, the band released the LP Machine Head including, among others: “Highway Star” and “Smoke on the Water” (with an intro banned in many guitar stores due to staff saturation).

That same year, between August 15 and 17, they played at the Festival Hall in Osaka and the Budokan in Tokyo to record one of the best live rock albums. The lineup at that time included Blackmore, Gillan, Lord, Glover, and Paice.

Below, I leave you with “Highway Star” as they sounded live in those years.

Related posts

From COBOL to Agentic AI: Transforming the Software Lifecycle

Evolution of the software lifecycle applying AI and Agentic AI

Digital Transformation: Beyond Technology

In Digital Transformation, purpose and culture are more important than technology itself.

PROTOPÍA: get familiar with the term

> "Let's avoid the DYSTOPIA (...) > "Let's avoid the DYSTOPIA (...)

All opinions expressed on this blog are personal and do not represent those of any company or organization with which I collaborate.